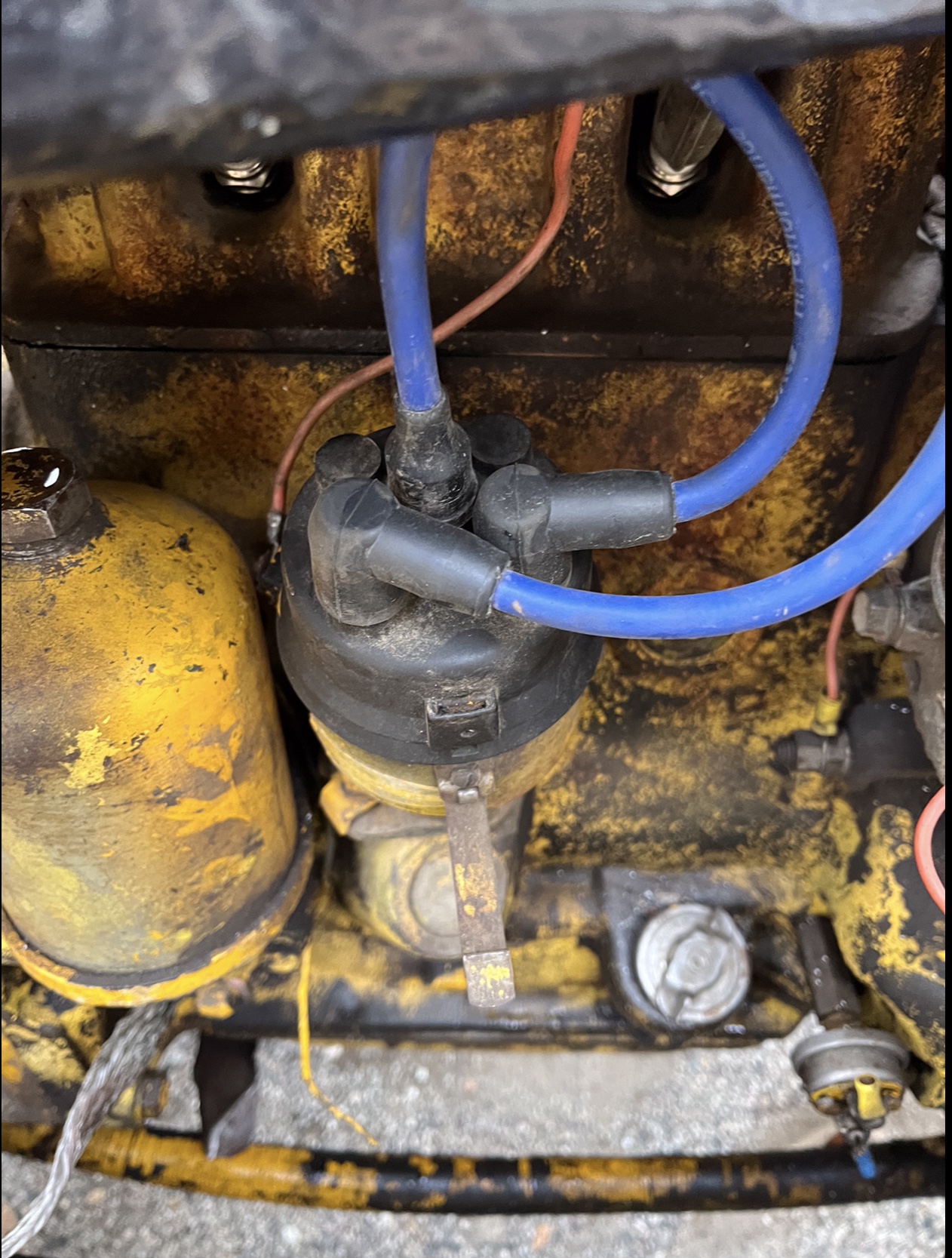

I cleaned and reinstalled the oil pan, new oil and filter. New points and condenser. Was able to get the timing set correctly. Adjusted the valves, they were all within a couple thousands.

Engine ran better but not great. Cleaned out the carburetor and put a kit in it. Cleaned out the fuel tank and put on a new fuel filter. Engine seems to be running very good now. Will need to push some dirt to know for sure.

Before the carburetor work the engine was running rich. I had 2 TSX 777 carburetors and was using the best parts of the 2 to make one. When I put It back on it still ran rich with the needle valve turned all the way in. After comparing the 2 main jets I saw that one was longer than the other but had the same length of needle valve. I put the shorter main jet in and put the carburetor back on and it adjusted like it should

Changed ALL the fluids, greased the rollers and sprockets with corn head grease and the rest of the machine with nlgi #2 grease.

Put new friction disks in the throttle control, there was nothing left of the originals.

When I picked this crawler up the clutch and brake pedal linkage / shaft were stuck together. I sprayed the linkage by the clutch pedal with penetrant a few times a day for a week, no change. Next I drove the left track up on a 6x6 block to give the shaft a downward slant.

Mixed up some ATF and acetone, applied that on and off for a few weeks. Finally got the 2 pedals to unlock from each other but only with a lot of force. So I went underneath and drilled a 3/16 hole in the clutch pedal hub to the shaft. That allowed me to force ATF / acetone into the shaft and bushing. The pedals started to loosen up after 1 application. After 3 shots of ATF the pedals were working like they should.

440 ICD 602 Blade 3Pt.hitch.

440 ICD 602 Blade Gearmatic winch.

440 ICD 64 6 way Blade Carco winch

440 ICD 831 Loader

440IC 831 Loader

1010c Diesel 612 6 Way Blade

North Central Washington State