Hello,

I recently bought a 420c It ran but needed odds and ends, needed the track adjusters rebuilt and things like that. I also teach a Heavy equipment class at a tech school.

I am loving this little 1957 crawler. I have been moving lots of snow and clearing my logging roads for February break. As I push snow with the crawler, if I attempt to turn even a little adjustment my clutches seem to make a grinding noise and slip, the same if going straight and contact something really solid that's no gonna move. both sides do it. We did have them apart, and cleaned them up. the fiber disks looked good, the metal ones were pitted and rusty but we lightly sanded them to clean them up. We did stupidly clean the fiber disks with diesel fuel. but allowed them to dry. Do you think that is why they are slipping or could it be bad pressure plates. I never did any real pushing before the teardown so I don't know if we caused this with the diesel fuel on the disks. I am considering buying new pressure plates and disks but that stuff is not free. The class and I have had a really good time learning about this crawler and working on it. We have all shop manuals, parts books, and operators manual so we know we put it back together correctly, and adjusted the steering. It steers great! just after it the clutches warm up from use its slips more than I like.

Thank you

420C Drive / steering clutches.

Re: 420C Drive / steering clutches.

Welcome to the Boards. And congratulations on being the 8000th member here!

Some of what you are experiencing may be due to the condition of the used discs and brake bands, since you don't have a history of operation before it was torn down. However cleaning the fiber/composite discs with diesel fuel is likely at least part of the problem. Never clean dry clutches or bands with petroleum products, the service manual says not to use any solution to clean composition discs. Only a solvent like a brake cleaner should be used. People have sprayed things like WD40 or penetrating oil on stuck clutch packs to try to free them up only to end up with slipping clutches/brakes, if they do break loose. The principal is no different than a dry engine clutch or dry brakes on a vehicle; oil, grease, petroleum products are the enemy.

Some have managed to make discs usable by baking in an oven and repeated cleaning with a brake cleaner. One told of packing his discs in a pail of floor dri and leaving them for an extended time (weeks) to pull the oil out of them. These methods may or may not work with passable results, I make no recommendation.

When you need parts. Lavoy, owner of this site, has a business repairing these vintage JD crawlers, and he sells parts for them. If you get parts from him you will be getting parts he uses in his shop and experience that is just a phone call away if you have an issue of need advice; not like most aftermarket sellers who just peddle cheap parts and may never have seen a 420C.

Some of what you are experiencing may be due to the condition of the used discs and brake bands, since you don't have a history of operation before it was torn down. However cleaning the fiber/composite discs with diesel fuel is likely at least part of the problem. Never clean dry clutches or bands with petroleum products, the service manual says not to use any solution to clean composition discs. Only a solvent like a brake cleaner should be used. People have sprayed things like WD40 or penetrating oil on stuck clutch packs to try to free them up only to end up with slipping clutches/brakes, if they do break loose. The principal is no different than a dry engine clutch or dry brakes on a vehicle; oil, grease, petroleum products are the enemy.

Some have managed to make discs usable by baking in an oven and repeated cleaning with a brake cleaner. One told of packing his discs in a pail of floor dri and leaving them for an extended time (weeks) to pull the oil out of them. These methods may or may not work with passable results, I make no recommendation.

When you need parts. Lavoy, owner of this site, has a business repairing these vintage JD crawlers, and he sells parts for them. If you get parts from him you will be getting parts he uses in his shop and experience that is just a phone call away if you have an issue of need advice; not like most aftermarket sellers who just peddle cheap parts and may never have seen a 420C.

Re: 420C Drive / steering clutches.

WOW 8000th!

I saw the speedy dry bucket thing for the disks too, seem brake clean and baking them might work as well.

I have been enjoying all the info on the Forum so far.

Thank you

I saw the speedy dry bucket thing for the disks too, seem brake clean and baking them might work as well.

I have been enjoying all the info on the Forum so far.

Thank you

- jimmydiesel

- 440 crawler

- Posts: 180

- Joined: Tue Oct 26, 2021 10:23 am

- Location: North Central Washington

Re: 420C Drive / steering clutches.

Vt420c

Welcome to the board, 8000 and growing.

I don’t have much 420 experience, the last time I worked on one was 1967 I was 11 and helping my dad. The steering clutches are mostly the same as the 440 so have worked on a few of them. I would second what Jim said above.

When you had the clutches out did you measure the thickness of the steel and fiber disk’s? The specifications are in the service manual.

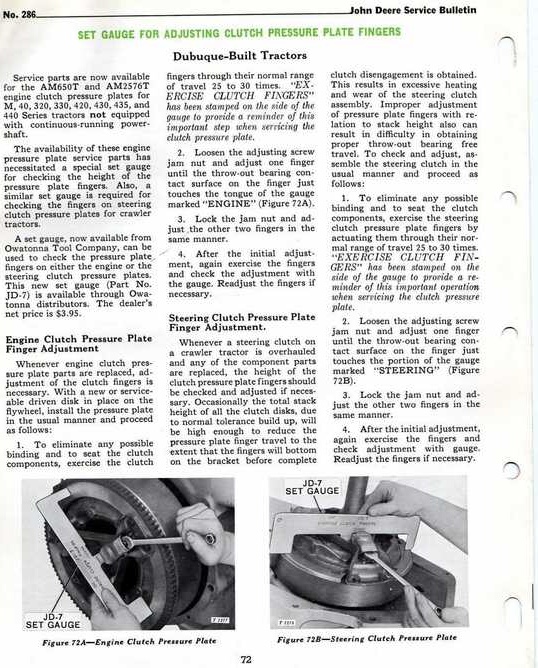

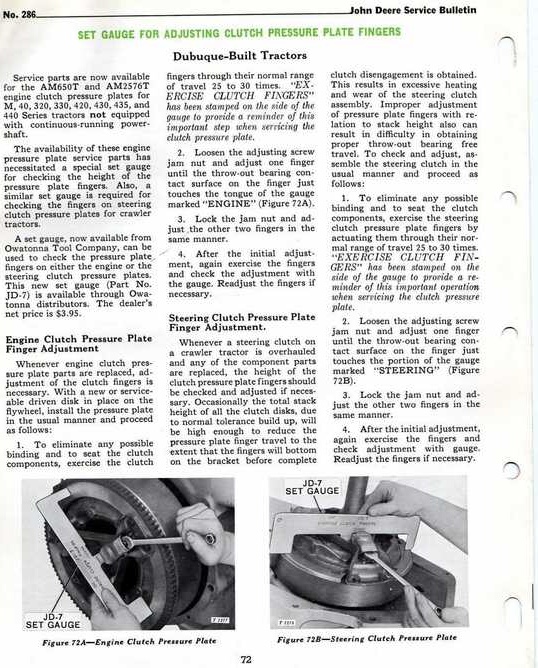

Did you adjust the pressure plate fingers using the JD-7 set gauge? Copy of John Deere service bulletin 286 below.

If the clutches are slipping because of the diesel fuel they may get better with more usage or not.

The JD-7 gauge is available as a reproduction. Lavoy may have them.

Welcome to the board, 8000 and growing.

I don’t have much 420 experience, the last time I worked on one was 1967 I was 11 and helping my dad. The steering clutches are mostly the same as the 440 so have worked on a few of them. I would second what Jim said above.

When you had the clutches out did you measure the thickness of the steel and fiber disk’s? The specifications are in the service manual.

Did you adjust the pressure plate fingers using the JD-7 set gauge? Copy of John Deere service bulletin 286 below.

If the clutches are slipping because of the diesel fuel they may get better with more usage or not.

The JD-7 gauge is available as a reproduction. Lavoy may have them.

440 ICD 602 Blade 3Pt.hitch.

440 ICD 602 Blade Gearmatic winch.

440 ICD 64 6 way Blade Carco winch

440 ICD 831 Loader

440IC 831 Loader

1010c Diesel 612 6 Way Blade

North Central Washington State

440 ICD 602 Blade Gearmatic winch.

440 ICD 64 6 way Blade Carco winch

440 ICD 831 Loader

440IC 831 Loader

1010c Diesel 612 6 Way Blade

North Central Washington State

Re: 420C Drive / steering clutches.

I never bothered measure the clutch pack disks thickness, mostly because the metal ones were rusty and pitted, and the fiber ones looked real nice. Somebody has been in to these clutches before. I don't have a JD-7 gauge yet but have been looking around for one on the cheap. So hopefully when I get my new pressure plates I can get one and set them up right. I might put some brake-clean to the packs and see how they do. As of now its pushing snow pretty good while my tractor was broken.

Re: 420C Drive / steering clutches.

I got my gauge from Lavoy.

Who is online

Users browsing this forum: No registered users and 41 guests