The first photo shows crawler less the seat and dozer blade hydraulic controls. The control valve has been leaking for some time so what a mess up under the valve.

This picture shows yet another fine piece of work in the history of this crawler. The stearing level broke at some point so why repair or replace it when you can just break out the old stick welder and weld the broken lever to the shaft. This is going to be fun.

This is the seat frame with some rotted away sections and more interesting repairs.

The pistons show the signs of ring leakage that you'd expect from the blue smoke.

Engine parts in the raw.

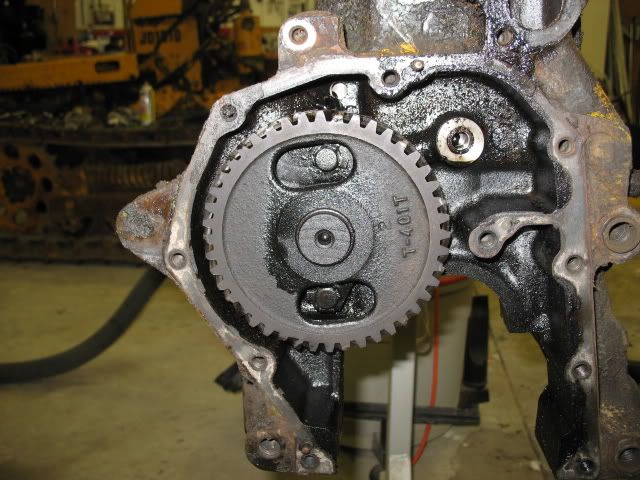

The camshaft drive gear with the interesting chips I mentioned in a previous post. Might be hard to see but it's only on a few of the teeth.

The block almost entirely stripped down. The sleeve and deck design of the 1010 engine is pretty cool except for the fact that the only source of the cylinder plate is Deere. I have to say that it's a really easy engine to work on and had some good thought in the design.

More later.